Description

Product details

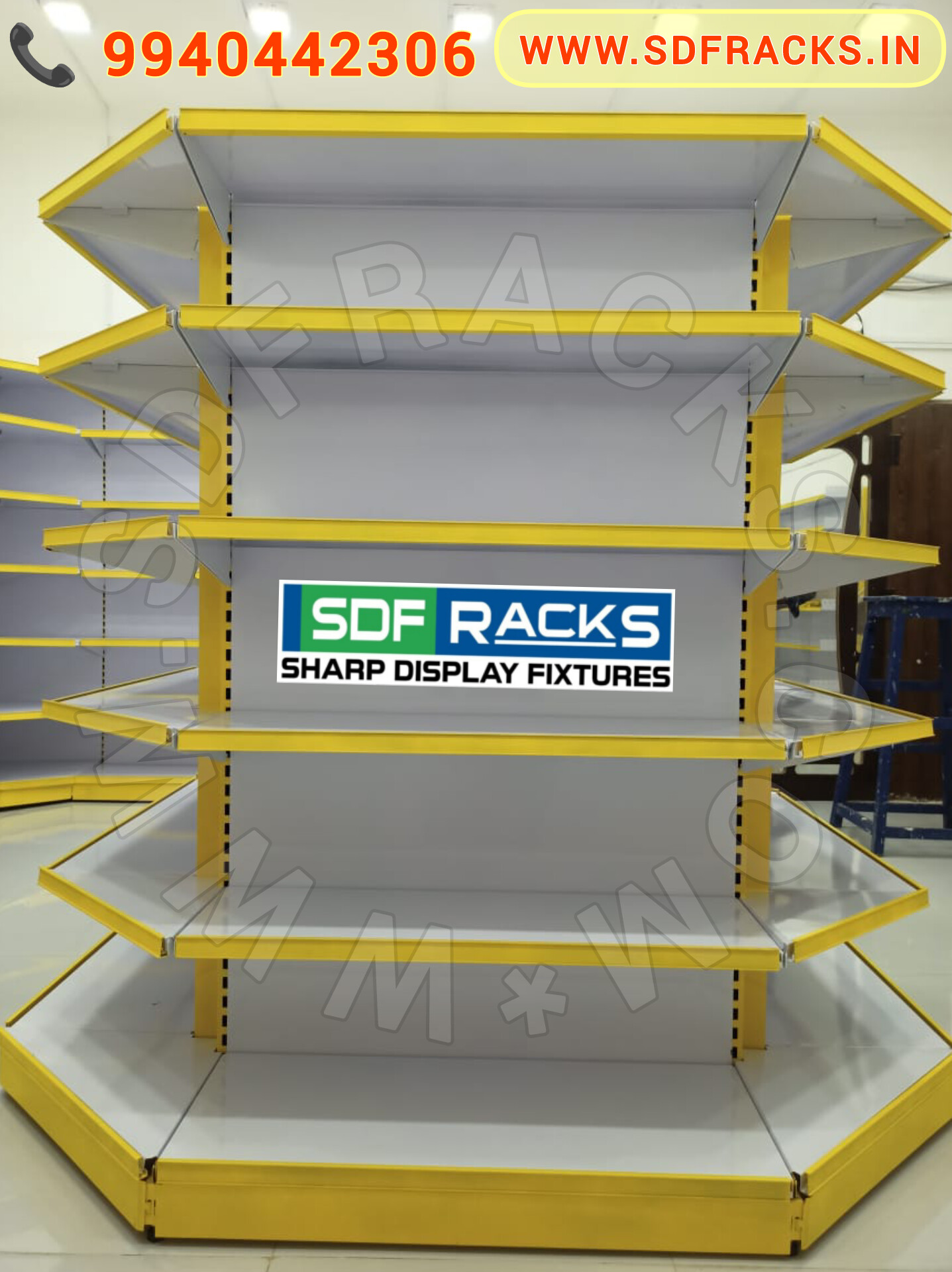

Manufacturing takes a comprehensive approach that combines precision technology with complex materials to create practical and sustainable storage solutions for industries For use in warehouses, retail types, or even homes, racks are essential for proper storage organization and design. The rack design process usually starts with design engineering. Engineers analyze specific requirements and features provided by customers or based on industry standards. Factors such as load capacity, dimensions, and environmental factors (such as temperature and humidity) are considered in this category. Computer-aided design (CAD) software is often used to develop detailed plans and drawings before production begins. Once the design is finalized, the process begins with material selection. Common rack materials include steel, aluminum, and sometimes plastic or composite materials. The selection is based on factors such as energy requirements, load limitations, and cost considerations. Steel, known for its strength and durability, is popular for heavy industrial applications. Construction follows material selection, where metal sheets or profiles are cut, shaped and welded to specific shapes. Precision cutting tools such as laser cutters and rolling water ensure dimensional accuracy, while bending machines form the metal into required shapes through processes such as welding, MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas), the parts safely Assembles and forms the shape of the rack Material surfaces are another important step in rack manufacturing, aimed at increasing durability and appearance. This can be various methods such as powder coating, which provides